INTEGRITY

IN EVERY LAYER.

Dual Laminate Piping and Vessels

Our Dual Laminate piping and vessel systems are meticulously designed to withstand the most aggressive chemical environments. By combining a thermoplastic corrosion-resistant liner with a robust fiberglass-reinforced plastic (FRP) structural layer, these systems offer exceptional chemical resistance and mechanical strength, making them ideal for industries where standard materials fall short.

Our dual laminate products are custom-engineered to meet specific process requirements, ensuring optimal performance and longevity. Whether dealing with high temperatures, aggressive chemicals, or stringent regulatory standards, we deliver solutions that provide peace of mind and operational efficiency.

-

Custom Engineered Designs: Tailored to meet exact job specifications, ensuring compatibility with existing systems and processes.

Thermoplastic Liners: Selection of liners such as PP, PVC, CPVC, ECTFE, and PVDF, chosen based on chemical resistance and temperature requirements.

Structural Integrity: FRP structural layer provides high mechanical strength, impact resistance, and durability.

Cost-Effective Solutions: Longer service life and reduced maintenance lead to lower total cost of ownership.

Versatile Applications: Suitable for a wide range of industries, including chemical processing, wastewater treatment, and more.

-

Chemical storage and processing tanks

Piping systems for corrosive fluids

Scrubbers and exhaust systems

Reactor vessels

Wastewater treatment components

FRP Piping Systems

Our custom-engineered FRP (Fiberglass Reinforced Plastic) piping systems are built to outperform in environments where corrosion, abrasion, and chemical attack are non-negotiable threats. Whether for new installations, replacements, or complex retrofits, our FRP piping is designed for long-term reliability, reduced maintenance, and simplified installation.

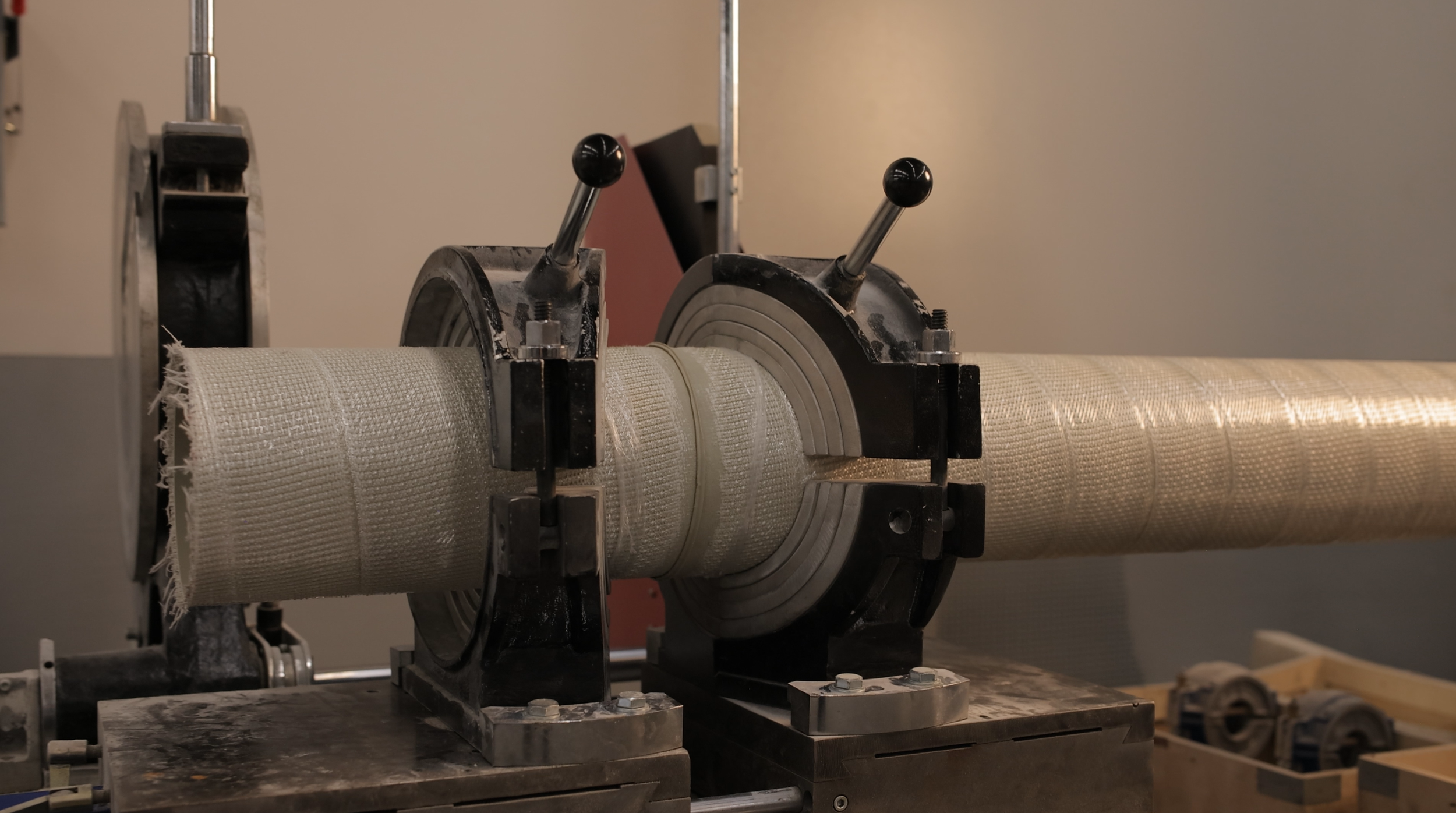

With corrosion and erosion allowances reaching up to 500 mils, our FRP pipes are manufactured using either Hand Lay-up or Filament Winding methods—selected based on your specific performance requirements. Every fitting is crafted by Hand Lay-up, incorporating a corrosion barrier to ensure superior internal protection.

Our advanced fabrication capabilities include shop-spooled subassemblies that can reduce joint count by up to 66%—minimizing leak points, accelerating installation, and boosting system integrity.

-

Custom pipe manufacturing with up to 500 mil corrosion/erosion allowance

Hand Lay-up and Filament Wound pipe options

All fittings manufactured via Hand Lay-up with corrosion barrier included

Shop-spooled subassemblies for faster install and fewer joints

Multiple joining methods designed for durability and ease of installation

-

Abrasion-resistant piping for demanding applications like Flue Gas Desulfurization (FGD)

FRPI Certification available for select pipe systems

Engineered pipe supports, anchors, and guides to ensure complete system reliability

Export crating available for international projects

Pipe replacement and field installation services by experienced An-Cor crews

-

Chemical processing plants

Power plant recirculating water systems

FGD systems

Wastewater treatment facilities

Semiconductor and clean manufacturing environments

Our Fiberglass Reinforced Plastic (FRP) tanks are engineered to provide superior corrosion resistance and structural integrity for demanding industrial applications. Utilizing high-performance resin systems and precision fabrication techniques, our FRP tanks are designed to meet stringent standards, including ASME RTP-1 and FRPI specifications.

Ideal for chemical processing, water treatment, and various other industries, our tanks offer customizable solutions tailored to specific operational requirements.

FRP Tanks and Vessels

-

ASME RTP-1 Code Stamped (Full vacuum through 15 psig)

FRPI Certified

Pressure and vacuum vessels

Seal tanks

Storage, mix, reaction, and settling tanks

Rectangular vessels

Bins, hoppers, and silos

Stationary and portable units

Water traps, barometric condensers, filter boxes

Sinks, sumps, trays, pans, troughs, trenches

Field wound, manufactured, or fully fabricated assemblies

-

Vertical or horizontal orientation

Above ground, below grade, or fully underground

Mounted on flat foundations, elevated platforms, or steel superstructures

Flat, sloped, ASME dished, elliptical, and open-top head styles

30°, 45°, and 60° ASME toriconical bottoms

-

Hinged or removable covers

Agitator supports

Stuffing boxes, packing glands, shaft seals

Internal baffles and sparge pipes

Customized internals to support processing needs

Support clips, brackets, and insulation jackets

Level indicators, site glasses, calibration strips

Pressure relief devices and hazardous material labeling

Custom Fabrications and Equipment

We specialize in designing and manufacturing custom fiberglass-reinforced plastic (FRP) equipment that meets the specific needs of our clients. Leveraging the inherent versatility of FRP, we create solutions that address complex design, space, and corrosion challenges across various industries.

Our experienced design and engineering team collaborates closely with clients to develop equipment that not only fits seamlessly into existing systems but also enhances performance and longevity. From concept to completion, we ensure each project is executed with precision and attention to detail.

-

Bespoke Designs: Equipment tailored to your exact specifications, ensuring optimal integration and functionality.

Material Versatility: Utilization of various thermoplastics and resins to meet specific chemical resistance and structural requirements.

Advanced Fabrication Techniques: Employing hand lay-up, filament winding, and other methods to achieve desired shapes and strengths.

Quality Assurance: Rigorous testing and inspection protocols to ensure durability and compliance with industry standards.

-

Troughs

Mobile Kettles

Chlorine Gas Seal Pots

Specialized Tanks and Vessels

Custom Piping Systems

Unique Structural Components

COMPREHENSIVE FRP SOLUTIONS FOR INDUSTRIAL INFRASTRUCTURE

Ventilation Equipment

We manufacture custom ductwork, hoods, and flow control devices for the effective collection and management of corrosive fumes and gases. Our offerings include round and rectangular ductwork, canopy hoods, vertical updraft and downdraft hoods, wrap-around and tunnel hoods, as well as integral or flanged flow control devices like butterfly dampers, blast gates, and louvers.

Stacks and Chimney Liners

We design and manufacture FRP stacks and chimney liners that deliver long-term reliability in even the harshest exhaust environments. Whether freestanding, guyed, or guided, our stacks are engineered to meet the specific structural and process demands of your facility—customized for virtually any height or diameter.

Our stacks can be seamlessly integrated with other equipment, such as scrubbers, with all structural loads and moments carefully evaluated for performance and safety. Chimney liners made by An-Cor provide unmatched corrosion protection for both masonry and steel chimneys, dramatically extending the life of critical infrastructure.

For specialized needs, our stacks and liners can be built with electrically conductive materials for static electricity bleed-off and fire retardant resins that meet ASTM E84 Class I and Class II flame spread ratings.

We provide a range of structural FRP components, including ladders, platforms, handrails, and staircases, designed to complement our tanks, vessels, scrubbers, and stacks. Each structure is prefabricated and prefit to minimize installation time and ensure a precise fit.

Structural Components

OUR PRODUCTS ARE BUILT TO LAST.

At An-Cor, we don’t just build FRP tanks and vessels—we engineer custom, corrosion-resistant solutions built to withstand harsh chemicals, extreme temperatures, and tough operating conditions.

Our high-performance FRP products utilize industry-leading thermoset resins, including:

Polyester, Epoxy Vinyl Ester, Bisphenol-A, Novolac, & Brominated Epoxy Vinyl Ester

Reinforcements ensure exceptional durability with:

C-glass, Carbon, & Synthetic Veils

E-glass & ECR Glass Mat

Woven Roving & Continuous Strand Roving

For enhanced corrosion protection, our dual laminate solutions combine FRP reinforcements with thermoplastic liners such as:

PP, PVC, CPVC, ECTFE (Halar®), & PVDF (Kynar®)

We offer standardized tooling (1”–14’ ID) and custom sizing for project-specific needs.

VERSATILE MATERIALS &

ADVANCED MANUFACTURING METHODS

Our team has extensive experience working with a wide range of high-performance resins, including polyester, vinyl ester, and furfural alcohol (furan) resins, along with C-Glass, ECR Glass, synthetic polyester, and carbon surface veils.

We utilize multiple fabrication techniques, including:

✔ Hand Lay-up – Ideal for complex, custom shapes

✔ Spray-up – Efficient for large-scale production

✔ Filament Winding – Provides superior structural integrity

✔ Vacuum Infusion – Ensures high-strength, lightweight components

Additionally, our equipment can be designed with abrasion-resistant, electrically conductive, and fire-retardant properties, enhancing erosion resistance, static electricity bleed-off, and flame spread control.

An-Cor’s products are fabricated at our state-of-the-art facility in New York, as well as on-site at customer construction locations worldwide. We manufacture equipment ranging from ¾” to 14’ in diameter, with larger sizes produced directly in the field. Our facilities are fully equipped with advanced lighting, heating, ventilation, and machining capabilities, allowing us to handle projects of any scale.

PRECISION MANUFACTURING

& GLOBAL CAPABILITIES

INDUSTRIES

WE PROTECT

Let An-Cor Industrial Plastics help solve your corrosion challenges as An-Cor has done in numerous industrial environments such as Chemical Process, Chlor-Alkali, Commercial, Cooling Tower, Desalination, Energy, Food & Agriculture, Industrial Water, Infrastructure, Metals & Mining, Oil & Gas, Petrochemical, Pollution Control, Pulp & Paper and Semiconductor.

QUALITY FRP COMPOSITES

TRUSTED FOR CORROSIVE CHALLENGES.

LET’S BUILD

SOMETHING THAT LASTS

At An-Cor, we specialize in high-performance, corrosion-resistant solutions built to withstand the toughest environments. Whether you need a custom-engineered system or expert guidance on your next project, our team is ready to help. Fill out the form below, and let’s start the conversation.